Preparing Your Diesel Engine for Cruising

29th May 2023

For many coastal cruisers, there’s nothing more pleasurable than sitting at anchor in a secluded cove of northern British Columbia or southeast Alaska. Many of us do just that every year, cruising for two to five months at a time. But what if you are new to a diesel engine and/or extended cruising? How do you prepare to ensure the boat’s power-plant is ready for the challenge?

Problems will arise but many can be prevented with pre-trip preventive maintenance. Failures are inevitable; and it’s all about reducing the odds of failure and how you handle the issues during the voyage that will contribute to the quality of the experience.

First, make sure to complete all the scheduled maintenance recommended by the engine and transmission manufactures. This includes looking under the hood, something we all have gotten out of practice of doing since diesels have become so reliable. An engine-room inspection only takes a few minutes and could prevent an expensive breakdown.

Obviously, engine oil level is crucial, diesels won’t run very long without it, but don’t obsess over keeping the oil exactly at the full mark. Too much oil can mean it is being diluted by diesel fuel, and cloudiness of milkiness indicates water contamination; either case requires immediate attention. Engine oil shouldn’t smell like fuel, nor should it feel gritty, and it’s normal for diesel engines to turn their oil black.

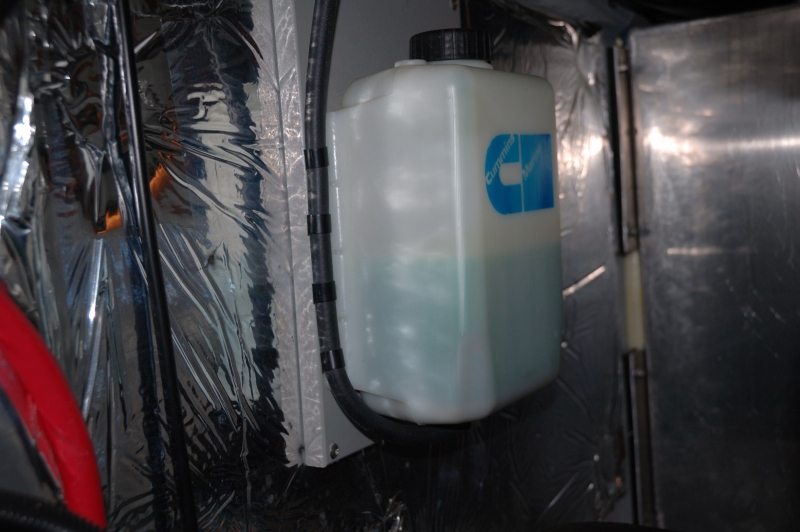

When working properly, clear plastic reservoirs on most boats provide visual reference of engine coolant level, but an improperly functioning heat exchanger cap or pinhole in the hose that connects the reservoir to the heat exchanger may prevent fluid from siphoning from the reservoir. If the reservoir is low when the engine is cold and near full when the engine is hot, it’s likely working properly.

Clear plastic reservoir provides visual of coolant level

Inspect the engine for oil, fuel, seawater, or coolant leaks. A mirror and flashlight can help your search. Black soot around the manifold, turbos or exhaust risers indicates exhaust leaks, which are particularly damaging as the abrasive soot clogs air filters and wears cylinder linings. Inspect fuel filters bowls with a flashlight, looking for telltale light-coffee-colored layer of sludge in the bottom that indicates water in the fuel or the heavy sediment that suggests clogged filters; also check seawater strainers for debris.

Recommend servicing seawater pumps annually, and clean and test cooling system every two or three years. Belts, hoses, clamps, and motor mounts must be inspected. Valve adjustments vary by engine manufacture.

Belts should be inspected and spares onboard

Next, take one of the many diesel engine classes offered.

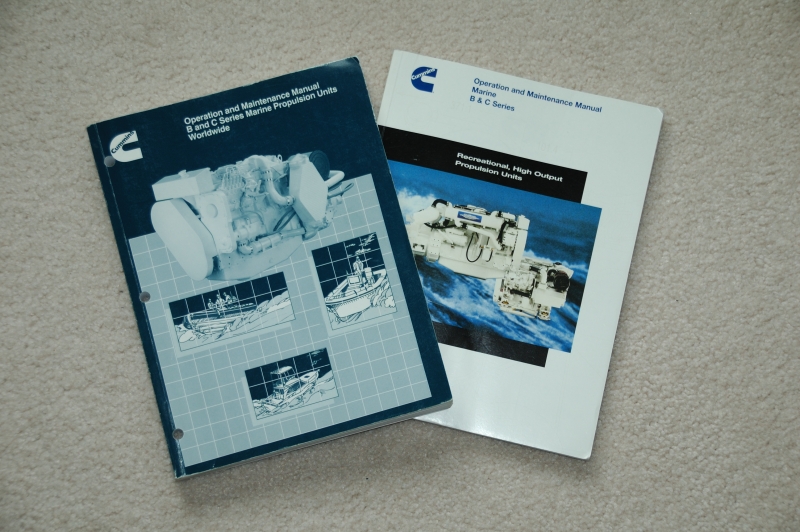

Second, take the operator’s manual into your engine room, find a comfortable place to sit and identify all major components while reviewing maintenance and service topics. Doing so will not only assist in understanding exactly where things are but also identify any special parts and/or tools needed to deal with them.

Grab the operator’s manual and spend some time in the engine room

Third, find the names of engine distributors, dealers, and authorized service centers along the route. Also, make sure you have a service and parts manual along with serial number of the engine and transmission; many technicians can help if they have this information. Purchase the correct spares, enough engine lube oil and filters required during your cruise, power steering fluid and transmission oil and filters, primary and secondary fuel filters, and a couple gallons of antifreeze.

With the introduction of Ultra Low Sulfur Diesel; engines have a higher likelihood of clogged primary fuel filters due to excess microbial growth. Primary fuel filters are usually located on a bulkhead close by the engine and is the first line of defense for filtering the diesel before it hits the very sensitive injectors. Some engines will have two primary filters that have a selector switch. The purpose of those valves is to run all the diesel through one filter and keep the other one clean as a backup. Don’t run on both filters. Run on ONE filter at a time. This saves having to swap out a filter mid trip because it’s clogged with microbial growth that tends to grow more freely in the Ultra Lower Sulfar Diesel we mentioned earlier. If you have only one primary fuel filter. Learn how it’s changed. Because it could be the difference between getting home or not.

Also, extra drive belts, air-cleaner element, raw-water pump impeller, gaskets and seals for sea strainers, replacement zincs for the heat exchanger, a selection of hose clamps and tie-wraps, and spare fuses and relays, are good to have

And don’t forget the correct tools. If plans include remote locations, carry an extra alternator, a complete sea-water pump, a set of spare injectors, and a complete gasket set. Most engine distributors have “cruise kits” available with many of the aforementioned items.

Once all the prep work is complete, the spares and tools are properly stowed and there is nothing sitting loose that could be thrown around the engine room during rough water conditions, you’re ready to give the command to cast-off.

Now, all that’s left to do is kick back and enjoy one of those secluded coves with peace of mind!