Don’t Let Your Shore Power Fail You

29th April 2022

When was the last time you inspected your boats shore-power cord? Regular inspections of the cord and its connection points will ensure that your boat’s AC power demands are being met. Electrical power flows from the receptacle on the dock to the shore power cord plug (male), and from the shore power cord connector (female) to the boat inlet. Knowing these terms will ultimately help you diagnose power troubles.

Typically, the two most-frequent causes of marine electrical troubles are overheating and corrosion from saltwater immersion. Too often, boat owners tend to ignore the warning signs and let matters progress until their power fails.

Examine the plugs at each end. Yes, they are supposedly corrosion resistant, but they can corrode, especially if exposed to salt water. If the metal prongs are bent, straighten them carefully with a pair of pliers. If there are signs of corrosion or oxidation, clean the prongs by rubbing them with a piece of very fine emery cloth. Then spray them with a moisture-displacing protective lubricant that is safe for use on electronic equipment.

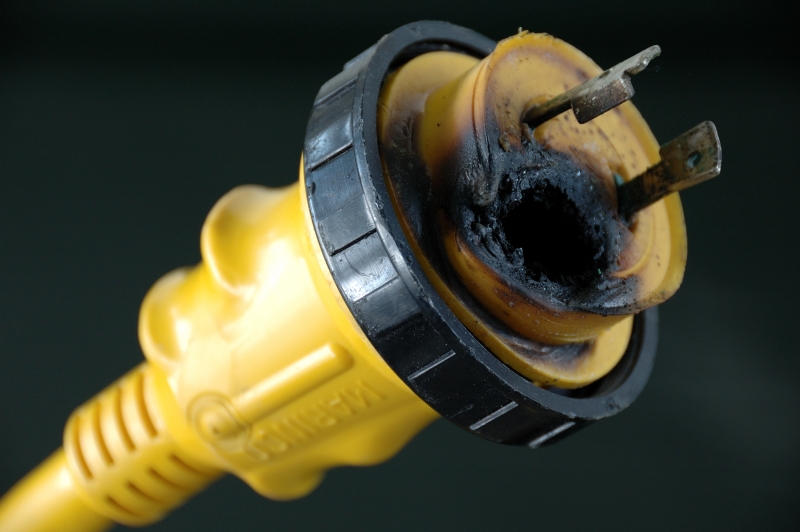

If the prongs are discolored or burnt, this indicates that the plug has overheated, probably due to arcing while it was plugged in, and it should be replaced. Arcing and overheating can be the result of a dock receptacle that is loose or defective, so check out the receptacle at your marina. If it is discolored or corroded, or if it is loose, have the marina maintenance manager replace it; otherwise, your new plug will also start to arc and overheat.

Remember that arcing and overheating can also occur when a plug is not pushed all the way into its outlet and then locked in place (always firmly turn a twist-lock type plug into place). Most marine plugs have rubber covers that fit over them to help keep out water; always make sure these covers are snugly in place after the cord has been plugged in.

When replacing a bad plug with a new one, don’t simply disconnect the original wires from the plug’s terminals, because the ends of these wires may have been scorched or broken off. Instead, completely cut off the end of the cord a few inches from the plug and start from scratch by removing the insulation to expose clean new wire ends.

In addition to checking the plugs at each end, give the entire length of shore cable a careful inspection. If the yellow insulation cover is dirty, it can be cleaned with a fender cleaner. Look for cuts, cracks or badly chafed areas on the insulation and patch these with three layers of electric insulation tape, overlapping each layer so it goes past the previous layer. However, if the cord has lots of defects, or if there are places where the bare wires are exposed, it’s best to play it safe and replace that cord entirely.

Following these few basic steps will help reduce the risk of any mishaps!

(Deane Hislop – In Partnership with Freedom Marine)